laser welding is the preferred welding method in the medical and aerospace industries, where even the slightest imperfection can lead to failure. Laser welding can join a wide range of materials, from metals to plastics to ceramics.

Laser welding provides precision that traditional welding methods cannot. This type of welding focuses a beam of light that can sometimes be thinner than a human hair, creating incredibly strong and clean welds without the risk of distortion.

KEY TAKEAWAYS

Laser Welding Works on a Variety of Materials – It is highly effective for metals like stainless steel, aluminum, titanium, copper, carbon steel, and nickel alloys, as well as non-metals like plastics, ceramics, and glass.

Precision and Strength – Laser welding creates strong, clean welds with minimal heat distortion, making it ideal for both high-strength materials and delicate applications.

Table of Contents

WHAT IS LASER WELDING?

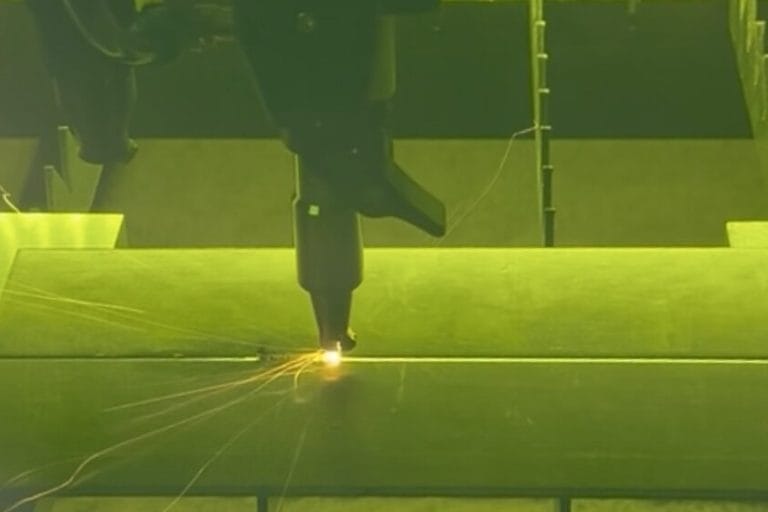

Laser welding is a powerful technology that uses a highly concentrated beam of light to melt and fuse materials with pinpoint accuracy. Unlike traditional welding methods, which broadly heat the material and risk distortion, laser welding applies intense heat to an extremely focused area, often as narrow as a fraction of a millimeter. This precise control not only minimizes thermal damage but also makes laser welding ideal for joining thin, delicate components or materials that require deep, narrow welds (some laser systems penetrate as deep as 100mm or 4″). Laser welding works on most materials: stainless steel, aluminum, copper, or even advanced engineered plastics. Because the heat-affected zone (HAZ) is so small, parts retain their original strength and dimensional accuracy, making laser welding essential in industries like aerospace, automotive, electronics, and medical device manufacturing, where precision and strength are critical.

HOW DOES LASER WELDING WORK?

Laser welding works by using a highly focused beam of coherent light (essentially, intense energy concentrated into a tiny spot) to rapidly melt and fuse materials together. When the laser beam hits the surface, most of its energy is absorbed by the material, generating extreme localized heat that almost instantly melts and even vaporizes some of the metal. The molten pool then quickly solidifies into a robust, precise weld joint as the laser moves along the seam. The exact depth and width of the weld can be precisely controlled by adjusting parameters such as laser power, beam focal point, wobble frequency, wobble width, wobble pattern, and pulse cycle shape. Because of this tight control and minimal heat input, laser welding achieves deep penetration welds with exceptionally low distortion. This makes laser welding ideal for precision assemblies, complex geometries, and materials that are traditionally challenging to weld with other methods.

Laser welding is particularly advantageous for projects with:

- Long, simple geometries

- Thick-to-thin or multi-alloy joints

- High-precision applications

- Heat-sensitive assemblies

- Hard-to-reach joints

- Need for repeatable quality across batches

METALS THAT CAN BE WELDED WITH A FIBER LASER

Laser welding is especially popular in metal fabrication because of its ability to handle different types of metals, from the toughest alloys to more lightweight materials. Here’s some of the metals that laser welding can handle:

1. STAINLESS STEEL

Stainless steel is everywhere for a reason—it’s strong, holds up in harsh environments, and doesn’t rust. You see it in food-grade equipment, surgical tools, chemical tanks, you name it. But welding stainless the right way takes a bit of finesse. It’s not just about getting two pieces to fuse. You have to manage heat input carefully, or you end up with warping, sugaring on the backside, or even changes in the chromium content that can wreck corrosion resistance.

TIG is usually the go-to for clean welds, but it’s slow and easy to overheat if you’re not careful. That’s where laser welding steps in. Because the beam is so focused, you get deep penetration without lighting up the whole part. Less heat means less distortion, which is critical when you’re working on thin-wall tubing or precision parts.

We ran a study for one of our customers in the sheet metal manufacturing industry. Laser welding gave us 67% less distortion compared to TIG, and we didn’t need to do any post-weld straightening.

2. ALUMINUM

Aluminum is a great material. It’s strong, lightweight, and it machines like butter. That’s why you see it all over aerospace, automotive, and consumer products. But when it comes to welding, aluminum is a bit of a troublemaker. It’s highly reflective, meaning it doesn’t want to absorb laser energy the way steel does. A good chunk of that beam just bounces right off in the beginning, making it hard to get the puddle started. And once it does melt, it’s got high thermal conductivity, so the heat spreads out fast and can make the weld unpredictable. You also have to watch for porosity. Hydrogen gets in there fast if your prep isn’t perfect.

That said, laser welding can handle aluminum, but it takes the right approach. Fiber lasers, especially with pulsed mode, are the key. You hit it with a short, high-power pulse to break through that reflective barrier, then back off the power to keep the heat input low. The LightWELD 2000XR does this well – you get that initial punch to initiate the weld, and then it smooths out to avoid overheating or distortion. We’ve used this setup on everything from 5052 to 6061, and it’s been able to weld thin sheet and structural extrusions alike with clean penetration and minimal post-weld cleanup.

The biggest takeaway? You can weld aluminum with laser, but you’ve got to know what you’re doing. The machine helps, but technique and prep still matter.

3. TITANIUM

Titanium is a phenomenal material. It’s lightweight, incredibly strong, and practically immune to corrosion. That’s why you see it in jet engines, spacecraft, surgical implants, and race car components. But as any welder will tell you, titanium is also notoriously unforgiving to work with. It has a strong affinity for oxygen, nitrogen, and hydrogen at elevated temperatures, meaning even brief exposure to air while it’s hot can cause contamination, embrittlement, and weld failure. Traditional TIG welding demands a meticulously purged environment with trailing shields and gas coverage before, during, and after the weld. One small lapse in shielding, and the weld turns brittle and discolored.

Laser welding changes the game entirely. Because the heat is so concentrated and the weld zone is so small, the material spends far less time above its reactive threshold. That dramatically reduces the risk of oxidation and contamination. The process is fast, precise, and repeatable. It’s ideal for welding titanium in cleanroom-grade applications like medical implants and aerospace components. With proper shielding gas and setup, laser welding allows you to achieve aerospace-grade titanium welds without the headache of elaborate purge chambers or trailing cups. It’s one of the few processes that truly tames titanium.

5. CARBON STEEL

Carbon steel is the backbone of fabrication. It’s strong, affordable, and welds beautifully if you treat it right. You’ll find it in everything from building frames to truck chassis to heavy equipment. But for all its versatility, carbon steel still comes with its quirks, especially when you’re chasing clean welds and tight tolerances.

Usually, MIG or stick welding is the go-to for thicker carbon steel. It’s fast and forgiving, but it brings a lot of heat. That’s fine on heavy plate, but once you get into thinner material like tubing, sheet, or formed parts, excess heat leads to distortion, burn-through, and time-consuming rework.

Laser welding solves that by dialing the heat input way down without sacrificing penetration. It’s like having a scalpel instead of a hammer. On 16-gauge or 14-gauge mild steel, laser welding gives you crisp, narrow welds that need little to no grinding. But what’s impressive is how well it performs on thicker material too. Fiber lasers like the LightWELD 2000XR can handle up to 8mm (that’s 0-gauge steel) with a clean keyhole weld in a single pass. No preheat, no arc blow, no mess. That’s something even experienced arc welders have to respect.

And speaking of arc blow, that’s one headache you don’t deal with in laser. No magnetized part issues, no wandering arc, no fighting to keep the bead straight. The laser hits exactly where you aim, and it doesn’t flinch.

Bottom line: carbon steel may be basic, but laser welding elevates it. You get repeatability, less post-processing, and tighter control, which adds up fast in production.

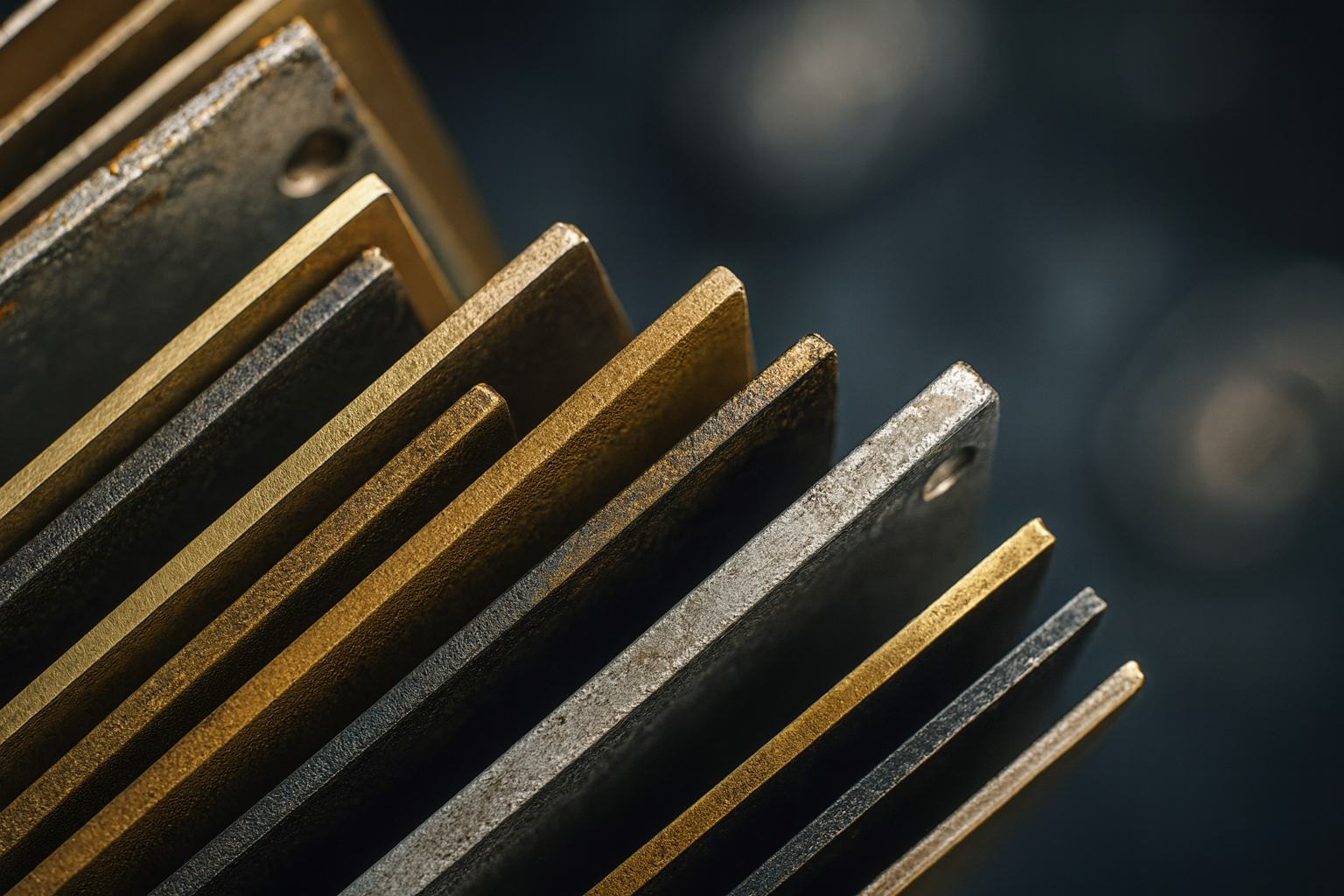

6. COPPER

Copper is a tricky material to weld. It’s soft, conducts heat like crazy, and reflects most of the energy you throw at it. That combination makes traditional welding a real challenge. The second you strike an arc, the heat just runs away from the joint. You end up cranking up the amps and fighting to keep the puddle stable. It also oxidizes quickly, so if your shielding gas isn’t perfect, the weld will go dirty fast.

Now here’s where laser welding comes into play. Copper reflects infrared light very efficiently, so standard continuous wave lasers don’t always cut it. But with a high-powered fiber laser and pulsed mode, you can punch through the reflectivity barrier and create a solid, repeatable weld. That short burst of energy raises the surface temp just enough for the metal to start absorbing the beam. Once it does, the weld stabilizes and flows beautifully. All without bathing the whole part in heat.

We’ve used this on electrical terminals, battery tabs, and heat sinks. With the right parameters, the welds come out strong and smooth, with no spatter and almost zero distortion. That’s critical when you’re dealing with delicate assemblies where electrical conductivity and thermal stability matter.

There are still challenges. You’ve got to dial in your focus, beam alignment, and gas shielding carefully. But compared to TIG or MIG, laser welding copper is like flipping on a light switch once it’s set up. Consistent, clean, and fast.

If you’ve ever spent hours trying to weld copper by hand, using a laser feels like cheating in the best possible way.

7. NICKEL ALLOYS

Nickel alloys are built to survive the harshest environments. High heat. Corrosive chemicals. Extreme pressure. That’s why they show up in nuclear plants, jet engines, and chemical processing. All the jobs where failure isn’t an option. But welding them is no walk in the park. They’re strong, but they don’t like to be rushed. And if you’re not careful, they’ll crack, warp, or harden in all the wrong ways.

The biggest challenge with nickel alloys is managing heat input. These materials tend to work-harden and form brittle microstructures if they cool too fast or unevenly. On top of that, many nickel alloys are sensitive to contamination. Any sulfur, phosphorous, or oxygen in the weld zone can lead to hot cracking or porosity. That means prep has to be flawless. And your shielding gas better be dialed in tight.

Traditionally, TIG has been the preferred method. You can control the arc and feather in the heat slowly. But it’s time-consuming and still prone to distortion and inconsistent results. That’s where laser welding shines. You can apply just enough heat, exactly where you need it, and nothing more. The narrow beam profile means less dilution, better control over penetration, and minimal distortion. You don’t overcook the surrounding metal. That’s a huge win when you’re working with precision components like turbine blades or reactor fittings.

With the right setup, a fiber laser can weld Inconel, Hastelloy, and Monel with beautiful results. Clean beads. Low porosity. High strength. And because the heat-affected zone is so small, you avoid many of the metallurgical problems that show up in traditional welding. Post-weld heat treatment is still sometimes necessary, depending on the alloy and application. But overall, laser welding gives you tighter control and fewer surprises.

It’s not plug-and-play. You need to know your beam parameters, shielding strategy, and joint design. But once it’s tuned in, laser welding gives you an edge that’s hard to beat in the world of nickel alloys.

8. DISSIMILAR METALS

Welding dissimilar metals is where most processes fall apart. You’re trying to join materials that expand at different rates, conduct heat differently, and form brittle intermetallic compounds if you’re not careful. It’s not just about melting two edges together. It’s about managing metallurgy at the fusion line.

I’ve seen people try to TIG aluminum to steel, copper to stainless, or titanium to nickel alloys. Almost always, you’re fighting against cracking, porosity, or joints that are just plain weak. You need transition layers. You need exotic filler metals. You need perfect gas coverage and post-weld heat treatment just to get something functional. And even then, it might not hold up under stress.

Laser welding changes what’s possible. With its pinpoint precision and low heat input, you can make solid dissimilar joints that traditional processes struggle with. Because the melt pool is so small and the energy so concentrated, you limit the size of the heat-affected zone. That reduces the chance of forming brittle intermetallic phases and keeps thermal stresses low.

One of the most powerful tools is beam wobble. By modulating the beam path slightly, you can better mix the two metals and manage the thermal profile at the fusion line. That technique has allowed us to create dissimilar welds that pass mechanical testing where other methods failed.

This isn’t entry-level work. It requires a deep understanding of material science, laser parameters, and real-world trial and error. But when it’s dialed in, laser welding opens doors that no other process can touch.

Get A Safety Enclosure

REFLECTIVITY AND LASER POWER

As we noted earlier, the higher the metal reflectivity is, the higher power we need to use to penetrate the same thickness. Let’s look at a metal reflectivity table below, kindly provided by the University of Columbia:

| Materials | k | n | R |

| Al | 8.50 | 1.75 | 0.91 |

| Cu | 6.93 | 0.15 | 0.99 |

| Fe | 4.44 | 3.81 | 0.64 |

| Mo | 3.55 | 3.83 | 0.57 |

| Ni | 5.26 | 2.62 | 0.74 |

| Pb | 5.40 | 1.41 | 0.84 |

| Ti | 4.0 | 3.8 | 0.63 |

| W | 3.52 | 3.04 | 0.58 |

| Zn | 3.48 | 2.88 | 0.58 |

| Sn | 1.60 | 4.70 | 0.46 |

| Glass | 0 | 1.5 | 0.04 |

When you fire a laser at metal, not all of that energy goes into melting. A large portion is reflected off the surface. That’s where R, the reflectivity, comes in. It’s the fraction of laser light that gets bounced back instead of absorbed. So, a reflectivity of 0.91 means 91 percent of your beam is wasted unless you overcome it. This is why certain metals like copper and aluminum are so hard to weld with a laser.

In this table, you also see n and k. These are the optical constants. n is the real part of the refractive index. It tells you how much the light bends when entering the material. k is the extinction coefficient. That tells you how much the light gets absorbed once it’s inside. These two values together determine how reflective the material is. These optical properties are functions of radiation wavelength and vary with temperature.

Now let’s break down some of the key entries.

Copper has an R of 0.99. That means it reflects 99 percent of the laser light at typical infrared wavelengths like 1070 nm. That’s brutal. You can hit it with 2000 watts and maybe only get 20 watts to actually melt the surface. That’s why copper needs a pulsed beam or a high enough peak power to momentarily exceed the reflectivity threshold. Once the surface melts, the reflectivity drops significantly, and the process stabilizes.

Aluminum is also highly reflective at room temperature, sitting at 0.91. Like copper, it gets easier to weld once the surface starts melting. But you have to hit it hard enough at first to break through that barrier. A pulsed fiber laser or high-brightness continuous beam is your best bet.

On the other hand, steel and nickel are far more laser-friendly. Mild steel, shown here as Fe, has an R of 0.64. That means 36 percent of the laser energy is absorbed right from the start. That’s plenty for stable keyhole welding. Nickel is similar, with an R of 0.74. These materials don’t require fancy tricks. You just need solid beam alignment and clean surface prep.

One interesting material here is titanium. It’s got an R of 0.63. That makes it a great candidate for laser welding. You get deep penetration and a narrow heat-affected zone, especially in argon shielding.

Tungsten and molybdenum fall in the middle range. They’re more reflective than steel but not nearly as bad as copper. They’re also dense and have high melting points, so you’ll need more laser energy overall, but it’ll be absorbed efficiently once the weld gets going.

Bottom line, this table shows you why some materials weld easily with lasers and others fight you at every step. If you’re working with high-R materials like copper or aluminum, you need to design your process around that. Use higher peak power. Use a short focal length for tighter beam concentration. Consider preheating or surface treatments. The LightWELD XR models use a single-mode fiber laser, which produces a much smaller, more focused spot. That tighter spot size allows for better energy density and deeper penetration, especially on highly reflective materials like copper. Once you get past the reflectivity barrier, the laser takes over and gives you precision and repeatability you won’t get with any other process.

CONCLUSION

Laser welding isn’t magic, but it can feel like it when you understand what’s happening at the surface. The material’s reflectivity, thermal conductivity, and chemical reactivity all play a role in whether the process succeeds or fails. Metals like copper and aluminum need high peak power and tight beam focus to get through the reflectivity wall. Others like steel and titanium are far more forgiving and absorb laser energy more readily.

Understanding the refractive index, the behavior of light at the surface, and how materials absorb energy is what separates guesswork from real process control. Tools like the LightWELD 2000XR, with their single-mode beam and pulsed mode, give you the precision to make even difficult materials weldable.

At the end of the day, laser welding is about matching the process to the material. Once you understand the physics, the rest falls into place. Clean welds, minimal distortion, and consistent results are all within reach.

FAQs

1. Why won’t my laser weld copper reliably?

Copper reflects most of the laser energy at room temperature. That makes it hard to start the weld. You need to use high peak power to overcome the reflectivity barrier and initiate melting. Once the surface is molten, absorption improves and the weld stabilizes. A single-mode fiber laser with a tight focus helps a lot. Pulsed mode is also useful to punch through that first layer of reflectivity.

2. Can I weld aluminum without warping the part?

Yes, but only with the right parameters. Aluminum conducts heat very quickly, which can cause wide heat-affected zones and distortion if you’re using traditional methods. Laser welding reduces this by focusing energy into a small, fast-moving spot. You still need to control your shielding gas and possibly use pulse shaping to get deep penetration without overheating the part.

3. Why do my stainless welds still show discoloration or oxidation after laser welding?

That usually comes down to poor gas shielding. Stainless steel oxidizes quickly when hot, especially if the shielding gas coverage is spotty. Make sure you’re using high-purity nitrogen or argon and that your nozzle design ensures proper coverage across the weld zone. Also, check that the part is clean and free of any surface contaminants.

4. Why am I seeing porosity when laser welding carbon steel?

Porosity is often caused by gas getting trapped in the weld pool. If you’re using pure argon, try switching to CO₂. Carbon steel can absorb CO₂, which helps the molten pool release trapped gases before solidifying. It’s a simple fix that often eliminates porosity issues.

About The Author

Chris Blench is a welding expert with 25+ years of experience in aerospace, defense, nuclear, and clean tech. He cofounded Mavericks Manufacturing Partners and MavWeld to tackle the most demanding manual, mechanized, and robotic welding challenges. He has deep expertise in welding procedure qualification and led Welding Engineering at General Atomics. Chris is committed to precision, quality, and re-shoring advanced manufacturing.