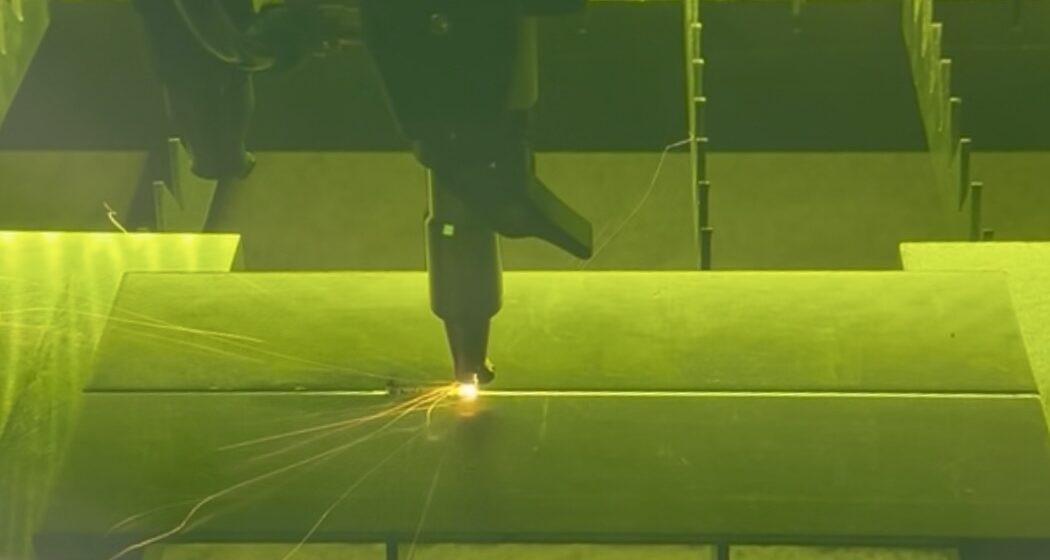

Laser welding automation is reshaping how high-precision components are manufactured. With its low heat input, high repeatability, and compatibility with robotics, laser welding offers a level of consistency that traditional welding simply cannot match. This article explains what laser welding automation is, why it matters, and how engineered parameters enable reliable, certifiable welds at scale.

Table of Contents

Why Laser Welding Automation?

Laser welding automation addresses the gap between modern manufacturing requirements and the limits of traditional welding processes. As tolerances tighten and quality requirements rise, consistency becomes a primary engineering constraint.

When Weld Quality Matters, Consistency Isn’t Optional

Manufacturers in aerospace, naval systems, energy, and precision fabrication are increasingly turning to laser welding because traditional processes can no longer meet the demands of modern hardware. When a weld is responsible for maintaining a pressure boundary, protecting a vacuum environment, or carrying structural load, every variable matters. Heat distortion, inconsistent penetration, and operator-dependent variability simply can’t be tolerated.

Laser welding addresses these issues at the source. It delivers:

- Ultra-low heat input for minimal distortion and tighter dimensional control

- Deep, narrow fusion for stronger joints and reduced rework

- Micron-level repeatability across long production runs

- High travel speeds without sacrificing weld integrity

- Process stability independent of operator technique, ensuring repeatability across shifts

However, the real advantage doesn’t come from the laser itself; it comes from parameter development, the engineering discipline that defines the exact process window needed to produce certifiable welds across materials and joint geometries.

Deep Understanding of the Laser Welding Process

Before automation can be designed, the weld must be fully understood. Most integrators can install a laser. Very few can develop a validated, qualification-ready parameter set for demanding applications. That is MAVWELD’s core strength.

We support programs that must comply with NAVSEA, AWS, ASME IX, and flight-hardware specifications, where reliability, traceability, and repeatability are non-negotiable. We specialize in welds that are difficult to control or qualify: thin-gauge stainless, aluminum, nickel alloys, titanium, copper, brass, and mixed-material interfaces.

For every project, we engineer and validate parameter sets that:

- Maintain stable penetration depth

- Control heat input and HAZ behavior

- Minimize porosity, cracking, and weld-start/weld-end defects

- Reduce or eliminate post-processing

- Meet or exceed engineering and code requirements

Standards We Have Qualified Welds To

Our parameter development and process qualification work spans multiple engineering and military codes used in aerospace, defense, and high-reliability manufacturing:

- AWS D1.1, D1.2, D1.3, D1.6, D1.9, D9.1, D17.1, D17.2

- ASME Section IX

- NAVSEA Technical Publications 248, 278, 1688, 1689

If your welds must pass engineering review, DE/NDE testing, or qualification to code, the stability of the laser process makes it easier to maintain consistent penetration, heat input, and HAZ behavior across production. With validated parameters and controlled motion, robotic laser welding holds a tight process window and minimizes variability from operator technique or part-to-part differences.

What MAVWELD Builds

MAVWELD designs and integrates laser welding automation systems for applications where weld quality, repeatability, and qualification requirements drive the system architecture.

Turnkey Laser Welding Automation Systems Engineered Around Your Welds

We build laser welding automation only after the weld is validated and repeatable.

Most integrators start with the robot. We start with the metallurgy.

Every project begins with parameter development, sample welding, and controlled testing. We develop weld parameters based on material behavior, joint geometry, penetration requirements, and thermal constraints. Where qualification is required, we develop welding procedures (WPS) and support procedure qualification (PQR) to ensure the process meets applicable code and customer requirements.

Only after the weld behavior is proven do we design the automation that reproduces that weld consistently at production scale.

Our turnkey laser welding systems typically include:

- Industrial fiber laser sources (single-mode or multimode, typically 1–3 kW+), selected for stable heat input, controlled penetration, and low distortion

- Six-axis robots or cobots matched to reach, stiffness, accuracy, and environmental requirements

- Precision-engineered fixturing to control distortion and maintain alignment during high-speed welding

- Custom enclosures and laser safety systems, including fume extraction and interlocks compliant with laser safety standards

- Optional seam-tracking sensors or inline laser profilometers for real-time process monitoring and quality verification

- Complete parameter documentation, weld maps, and recommended qualification pathways for AWS, ASME Section IX, or NAVSEA procedures

MAVWELD does not simply automate a motion path. We engineer the welding process first, then build robotic systems that deliver those parameters consistently. That is why organizations in aerospace, naval defense, energy, and R&D rely on our systems for qualification-driven, repeatable performance.

Example Applications

Laser welding is commonly applied to components where distortion, inconsistent penetration, or excessive heat input cannot be tolerated. The applications below illustrate where laser welding automation is most effective.

Proven Across High-Value, High-Precision Components

We support programs where weld quality directly determines safety, service life, and mission performance. Common applications include:

Tube-to-Tubesheet Welds on Heat Exchangers

Laser welding delivers consistent penetration and minimal distortion across hundreds or thousands of tube-to-tubesheet joints. This makes it well suited for naval, aerospace, and high-performance cooling systems where leak-tightness, uniform fusion, and repeatability are critical.

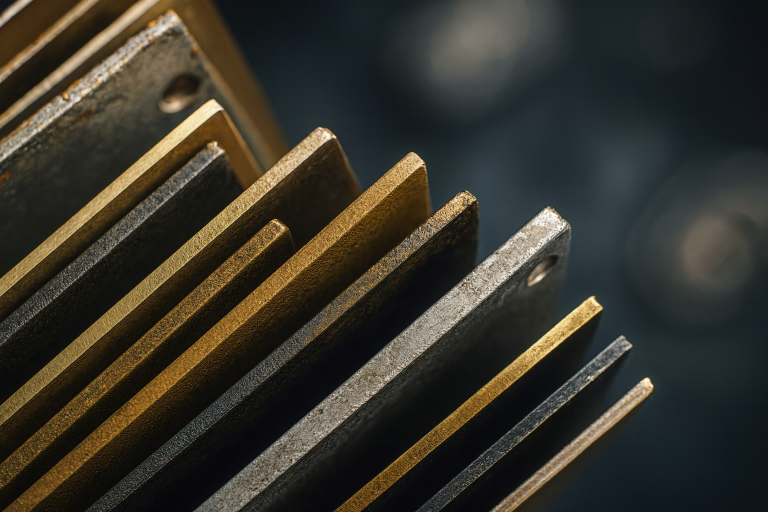

Battery Busbars and Power Modules

Low-heat laser welding enables reliable joining of aluminum, copper, and nickel-clad copper while protecting adjacent cells, insulation layers, and sensitive electronics. Controlled heat input minimizes damage, distortion, and changes in electrical resistance.

Thin-Gauge Stainless Assemblies

Laser welding produces clean, repeatable welds with minimal warping in thin-gauge stainless components. Common applications include trays, housings, vacuum components, enclosures, and lightweight brackets where flatness, surface quality, and dimensional control are required.

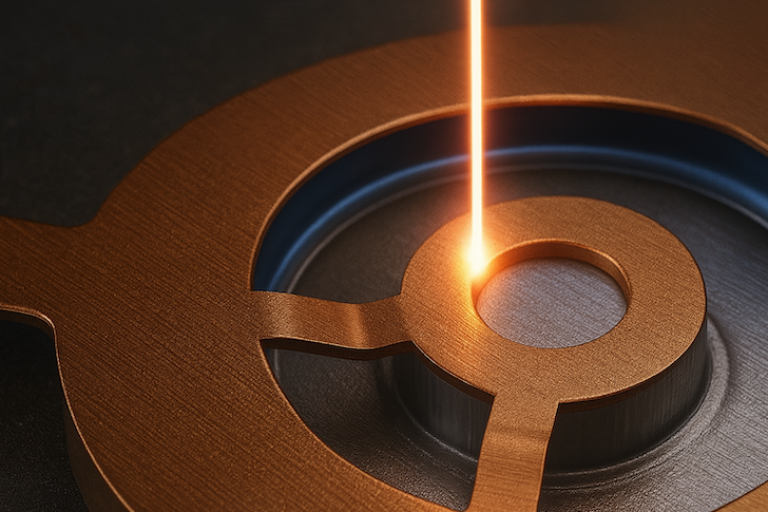

Aerospace and Spaceflight Hardware

Laser welding supports applications requiring narrow HAZ, controlled fusion profiles, and qualification to aerospace standards. Typical components include flight hardware, vacuum assemblies, precision actuators, and load-bearing structures that undergo inspection, NDE, and engineering review.

At each stage, we focus on the weld itself. Joint geometry, penetration requirements, metallurgical constraints, process stability, and DE/NDE expectations are defined first. The automation is then engineered to execute that weld consistently across production, without introducing variability.

How We Build Your Automation

Our team validates the weld first, then designs automation around a proven, qualification-ready process.

1. Technical Discovery and Feasibility Review

We review drawings, STEP files, weld symbols, material specifications, and applicable standards including NAVSEA, AWS D17.1, ASME Section IX, and customer requirements.

Joint design, fit-up tolerance, heat-sink behavior, and process risks are defined before system design begins.

2. Parameter Development and Sample Welding

We develop and document laser welding parameters specific to the joint and material, including power, speed, focus position, wobble settings, shielding gas, and pulse shaping. Sample welds are produced and evaluated through DE and NDE at a local lab if needed to establish a stable and repeatable process.

3. System Engineering and Architecture Design

After parameters are validated, we design the automation system.

Robot model, fixturing, laser optics, motion paths, sensing, controls, enclosure, fume extraction, and safety systems are engineered around the validated weld behavior.

4. Build, Integration, and Factory Acceptance

The system is built and integrated using the qualified parameters.

Factory Acceptance Testing is conducted under production-representative conditions to verify stability, repeatability, and documented quality.

5. Installation, Training, and Qualification Support

We install the system on site, train operators and engineers, and support WPS and PQR execution as required.

This ensures the production process meets engineering authority and customer qualification requirements

Trusted by Advanced Manufacturers and Mission-Critical Programs

We support organizations working across Navy programs, defense manufacturing, aerospace supply chains, spaceflight hardware, and high-end R&D.

Much of our work is protected by ITAR and customer confidentiality, but we bring the same rigor to every commercial system we deliver.

Our Customers Typically Operate in Environments Where:

- Welds must be certifiable, not just cosmetically clean

- Traceability, documentation, and process stability are mandatory

- Audits, inspections, and destructive tests are expected parts of production

- A welding process must withstand engineering review and avoid qualification drift

Our reputation is built on disciplined parameter development and welds that hold up under inspection.

Ready to Build a Repeatable, Qualified Laser Welding Process?

This is the point where technical feasibility turns into execution. If your application requires stable penetration, controlled heat input, and qualification-ready welds, the next step is to review your process.

Whether you are welding thin-gauge stainless assemblies, aerospace components, prototypes, or production parts, we develop and validate the weld parameters first, then design automation around a proven process.

We respond within 24 hours and engage directly on technical details.

Ready to improve your operations?

Tell us about your production challenges. We’ll find a way to help.

- No sales pressure. Honest answers from our experts

- Clear breakdown of your options

- Get clarity before you invest

About The Author

Ilya Petrov is the COO of MAVWELD, where he leads the company’s engineering efforts in laser welding and automation. He oversees process development, weld qualification, and system delivery for high-reliability industrial and defense applications, ensuring customer requirements are translated into production-ready solutions.