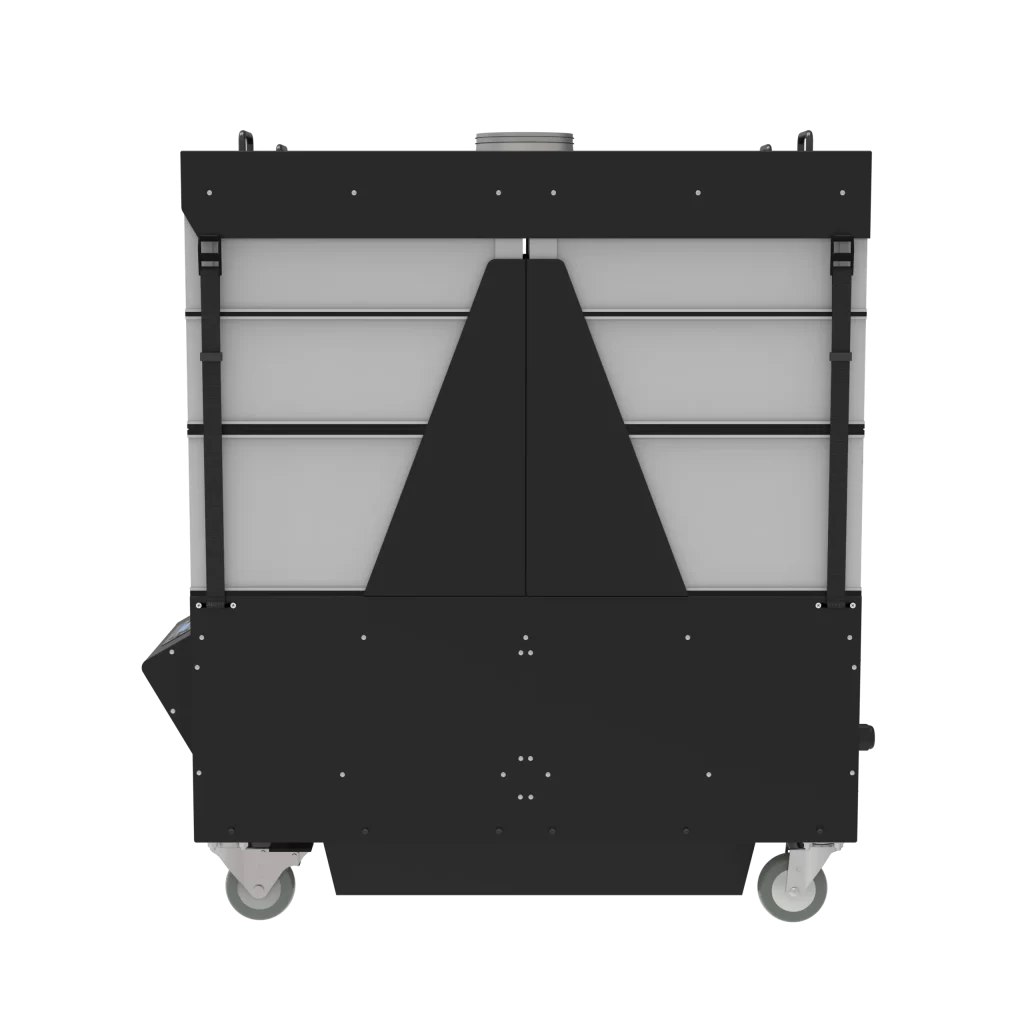

Fume Extractor for Laser Cutter [Expand XF by Filtrabox]

Price range: $13,095.00 through $19,095.00

Description

Expand XF Series fume extractor for laser cutter and engraver

The Expand XF Series is a professional fume extractor for laser cutter applications. It delivers intelligent airflow control and a modular 3-stage filtration stack that captures particulate and gases at the source, then recirculates clean air back to the workspace for safer laser cutting and laser engraving.

Why choose an Expand XF fume extractor for laser cutter workflows

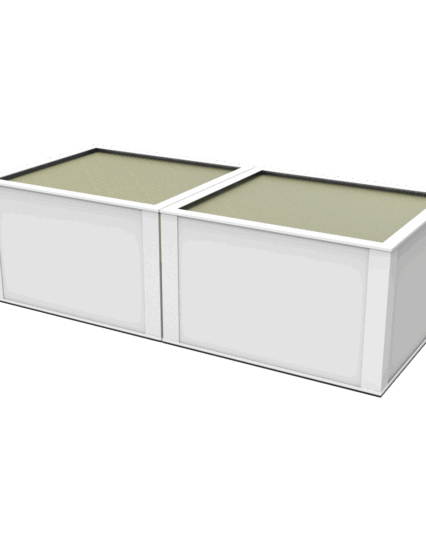

- 3-stage separated cartridges for targeted control: F9 prefilter for fine dust, HEPA 99.999% at 0.3 micron for ultrafine particulate, and a molecular gas filter with activated carbon and oxidizers for VOCs.

- Rigid aluminum filter frames and robust cabinet sealing minimize bypass under high negative pressure.

- Intelligent flow control maintains set airflow as filters load to stabilize capture at the hood.

- EZ-Link laser connectivity enables automatic start and stop to reduce energy use and extend filter life.

- Service-friendly modular design separates blower, electronics, and UI modules for quick field swaps.

Learn more about filtration and indoor air considerations at OSHA.gov. For welding fume safety and ventilation guidance, see OSHA resources.

Expand XF lineup comparison for laser cutter extraction

| Model | Airflow | Pre-filter | HEPA | Carbon Filter | Amps @ 240V | Noise level | Ideal for |

|---|---|---|---|---|---|---|---|

| XF1 | 235 CFM | 44 m² | 44 m² | 240 lbs | 6A | 62dB | Small laser systems and light-duty applications |

| XF2 | 2 × 235 CFM | 44 m² | 44 m² | 240 lbs | 12A | 62dB | Medium-duty applications with higher VOC generation |

| XF3 | 3 × 235 CFM | 44 m² | 44 m² | 115 lbs | 16A | 53dB | Heavy-duty applications requiring maximum filtration capacity |

| XF4 | 4 × 235 CFM | 44 m² | 44 m² | 240 lbs | 24A | 62dB | High-volume production environments and large laser systems |

| XF5 | 5 × 235 CFM | 44 m² | 44 m² | 240 lbs | 50A | 62dB | Extreme production environments |

| XF6 | 6 × 235 CFM | 44 m² | 44 m² | 240 lbs | 36A | 62dB | Ultra high-volume industrial production |

EZ-Link Laser Connectivity

Seamlessly integrate with your laser system for automated operation. The intelligent connectivity ensures the extractor runs only when needed, saving energy and extending filter life.

Modularity for Serviceability.

Our fume extractors comprise of many complex electronics components and sensors to monitor and control their performance. However, we have simplified the Filtrabox by consolidating the components into two simple and removable modules:

- Electronics Module: This module includes all the blower control and power systems.

- Blower Module: This module includes the blower and flow sensor.

- User Interface Module: This module includes all the components related user interface.

In the event of a field issue, our tech support need only focus on diagnosing three modules to quickly dispatch the appropriate module to you for immediate replacement. The modules are simple to replace with only a few plug-and-play wire harnesses – no tech experience required.

How a separated 3-stage fume extractor for laser cutter reduces cost

Different materials emit different dust-to-gas ratios. By keeping HEPA and gas filters separate in a fume extractor for laser cutter applications, you only replace the stage that is actually spent. For example, acrylic tends to exhaust more VOCs than dust, so the gas stage may need replacement sooner than the particulate stages. This approach reduces waste, lowers total cost of ownership, and maintains optimal capture performance.

All items ship within 5-7 business days

Additional information

| Weight | 360 lbs |

|---|---|

| Dimensions | 45 × 30 × 42 in |

| Select Model | XF-1, XF-2, XF-3, XF-4, XF-5, XF-6 |