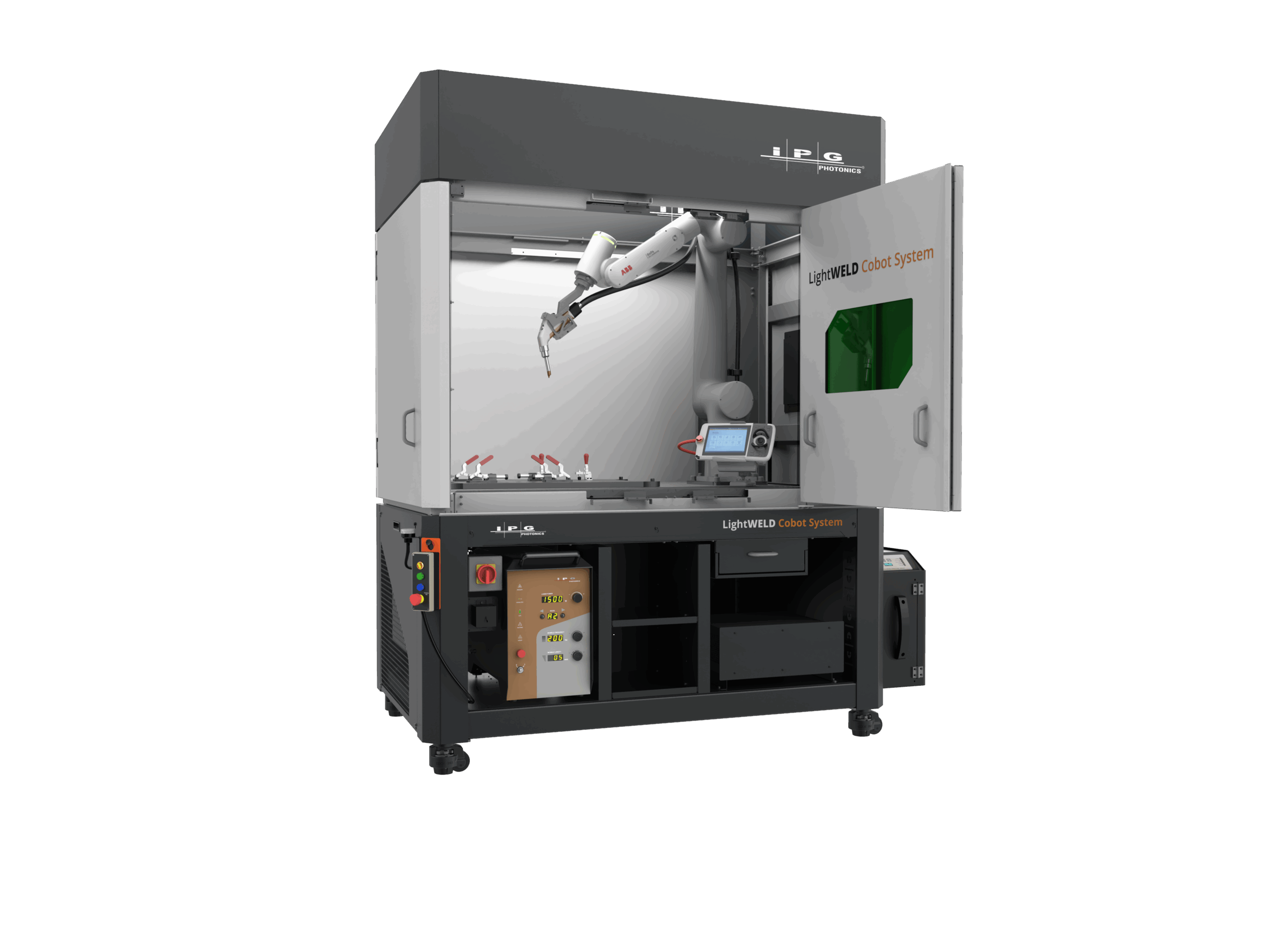

LightWELD Cobot by IPG

$189,744.00

Description

Turn-key system features:

▪ LightWELD Handheld Laser Welder

▪ ABB GoFa 12 6-axis cobot, controller and torch mounting cradle

▪ Industrial machine base with weld table

▪ LightWELD Cobot Command Interface

Ideal for high-mix, low-volume production orders.

▪ Easy to Program

▪ Repeatable Results

▪ Improved Quality

Programming a cobot is easy to learn:

▪ Manual Guided Teaching

▪ Single-button Waypoint Programming

▪ Intuitive Graphical User Interface

▪ Simple Block Based Programming

▪ Remote Control of LightWELD Parameters

▪ Remote Control of Wire Feeder Speed

▪ 2-in-1 Cobot and Manual Welding – flexible to

easily switch as needed

Benefits of Cobot Integration

Increased Efficiency: Cobots easily perform repetitive or physically demanding tasks, this frees up welders to focus on more skilled or strategic activities.

Flexibility: Cobots are designed to be easily reprogrammed and redeployed for different tasks. This flexibility allows manufacturers to quickly adapt to changes in production requirements

Cost-effectiveness: Compared to traditional industrial robots, cobots are more affordable to purchase, install, and maintain.

Enhanced Quality: Collaborative robots can be programmed to perform tasks with high precision and accuracy, resulting in consistent product quality.

Worker Empowerment: By offloading repetitive or monotonous tasks to cobots, human workers can focus on more meaningful and rewarding aspects of their jobs, such as problem-solving, creativity, and innovation.

All items ship within 5-7 business days

Additional information

| Weight | 1000 lbs |

|---|