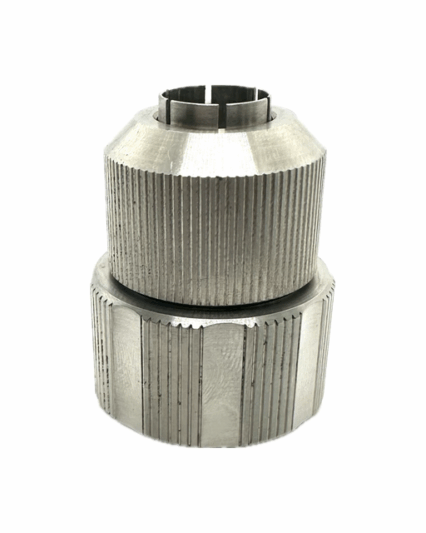

Steel Liner for Laser Wire Feeder

Price range: $31.00 through $46.00

Description

Liner for Laser Wire Feeder — Durable Steel Monocoil Options

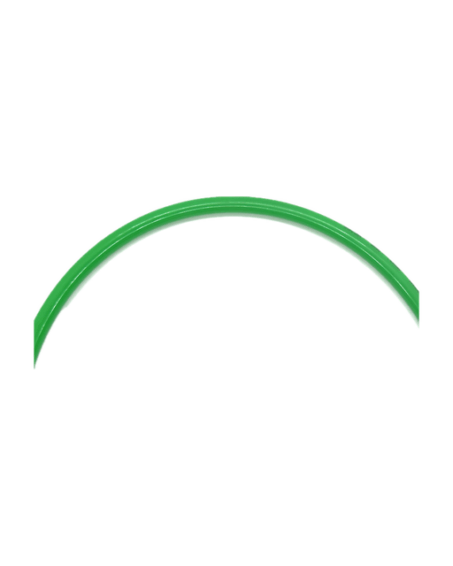

Upgrade your wire delivery with a premium liner for laser wire feeder systems designed to run clean, stable, and consistent. This steel monocoil liner reduces friction, protects the wire path from kinks, and keeps particulate out of the laser process. Whether you are welding or cladding with fiber laser welder, this liner for laser wire feeder maintains smooth feeding across common wire diameters and reel changes, so your bead quality stays repeatable.

Why this liner

- Monocoil steel construction for extended service life and improved push strength.

- Low drag interior for smooth, consistent feed rates at low and high speeds.

- Drop-in replacement for popular laser wire feeders including LightWELD wire feeder systems.

- Sized for fit and finish across 0.8 to 1.6 mm solid or cored laser wires.

- Clean process helps reduce birdnesting, burnback, and micro stoppages that disrupt laser travel.

Available configurations

Choose the length and diameter range that matches your feeder, gun, and process window:

- 10 ft liner for 0.8 mm to 1.1 mm wire

- 10 ft liner for 1.1 mm to 1.6 mm wire

- 15 ft liner for 0.8 mm to 1.1 mm wire

- 15 ft liner for 1.1 mm to 1.6 mm wire

Technical specifications

| Product type | Steel monocoil liner for laser wire feeder |

|---|---|

| Lengths | 10 ft, 15 ft |

| Wire diameter ranges | 0.8–1.1 mm or 1.1–1.6 mm |

| Compatibility | Designed for LightWELD wire feeder and most common laser wire feeder systems using standard liner interfaces |

| Material | Hardened steel monocoil with low friction inner path |

| Use cases | Laser welding, laser cladding, additive repair, precision overlay |

Performance benefits

- Stable feed that supports tight laser travel speed windows and minimizes spatter events.

- Improved uptime thanks to reduced friction and fewer feeder alarms related to drag or jams.

- Quality consistency with smoother starts and more uniform bead wetting on stainless and low alloy steels.

- Lower consumable cost because the monocoil build resists kinking and extends liner life.

Installation in 3 steps

- Measure and match your current liner length and the wire diameter you run most often.

- Remove and replace the old liner, routing the new liner straight through the conduit without sharp bends.

- Trim and seat per your feeder manual, then verify smooth feeding with a short jog before production.

How to choose the right configuration

Select the liner for laser wire feeder that matches your typical wire size. If you change wire sizes frequently, choose the range that centers your most common diameter. For long torch or complex routing, pick the 15 ft option to maintain gentle radii. For compact cells with short leads, the 10 ft option keeps the path tight and responsive.

Compatibility notes

This replacement liner is built as a direct fit for LightWELD wire feeder setups and other feeders that accept standard monocoil liners. Always verify end fittings and trim length against your specific torch and feeder documentation before use.

What is included

- One steel monocoil liner in your chosen length and diameter range

- Protective end caps for shipping

- Quick start install card

Ready to improve wire delivery? Select your configuration above and keep your laser cell running smooth and consistent.

All items ship within 5-7 business days

Additional information

| Weight | 1 lbs |

|---|---|

| Length | 10ft, 15ft |

| Size | 0.8–1.1 mm (0.030"-0.045"), 1.1–1.6 mm (0.045"-0.063") |