Most of us know what welding is, but what about laser welding? I was stunned when I first learned about it.

As technology advances humans find ways to make work easier. Thus, the invention of laser welding — an extremely advanced and efficient technique used across a multitude of industries for joining materials.

From aerospace and automotive to medical devices and electronics, laser welding is recognized for its precision, speed, and minimal heat distortion.

Key Takeaways

- High Precision and Speed: Laser welding allows for high accuracy and speed. It is ideal for applications requiring fine detail and dimensional accuracy.

- Minimal Heat-Affected Zone (HAZ): The concentrated heat input results in a smaller HAZ. This results in significantly lower heat distortion than from other welding methods like MIG and TIG.

- Versatility: Laser welding is capable of welding a wide range of materials, including carbon steels, stainless steel, aluminum, titanium, and various polymers.

- Automation Compatibility: The process integrates well with robotic systems because it allows for precise control without a plethora of additional sensors and feedback loops.

Table of Contents

WHAT IS LASER WELDING?

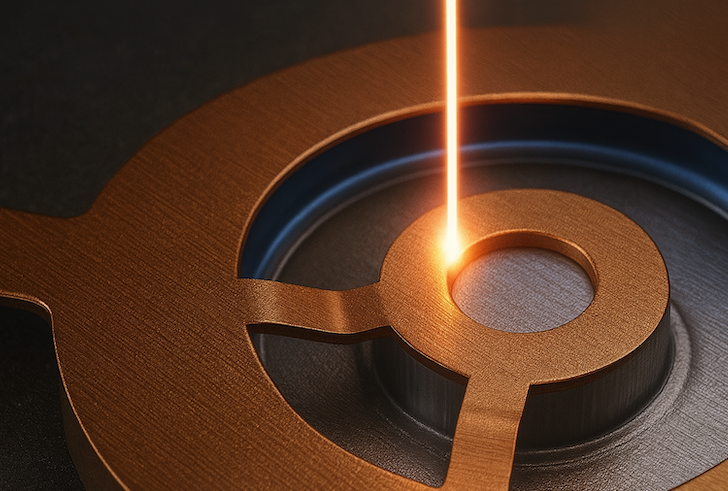

Laser welding is a powerful technology that uses a highly concentrated beam of light to melt and fuse materials with pinpoint accuracy. Unlike traditional welding methods, which broadly heat the material and risk distortion, laser welding applies intense heat to an extremely focused area, often as narrow as a fraction of a millimeter. This precise control not only minimizes thermal damage but also makes laser welding ideal for joining thin, delicate components or materials that require deep, narrow welds (some laser systems penetrate as deep as 100mm or 4″). Laser welding works on most materials: stainless steel, aluminum, copper, or even advanced engineered plastics. Because the heat-affected zone (HAZ) is so small, parts retain their original strength and dimensional accuracy, making laser welding essential in industries like aerospace, automotive, electronics, and medical device manufacturing, where precision and strength are critical.

HOW DOES LASER WELDING WORK?

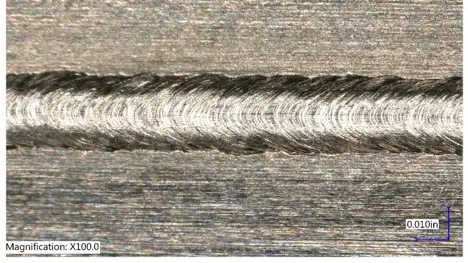

Laser welding works by using a highly focused beam of coherent light (essentially, intense energy concentrated into a tiny spot) to rapidly melt and fuse materials together. When the laser beam hits the surface, most of its energy is absorbed by the material, generating extreme localized heat that almost instantly melts and even vaporizes some of the metal. The molten pool then quickly solidifies into a robust, precise weld joint as the laser moves along the seam. The exact depth and width of the weld can be precisely controlled by adjusting parameters such as laser power, beam focal point, wobble frequency, wobble width, wobble pattern, and pulse cycle shape. Because of this tight control and minimal heat input, laser welding achieves deep penetration welds with exceptionally low distortion. This makes laser welding ideal for precision assemblies, complex geometries, and materials that are traditionally challenging to weld with other methods.

LASER WELDING: BASIC STEPS

Here’s an overview of the typical steps in the laser welding process:

- Preparation: First, clean the pieces to be welded (either with chemicals or with laser ablation), then properly align and fix them in place.

- Laser Beam Application: Next, direct the laser beam at the joint, where it will melt the material.

- Formation of the Weld: The molten material will then cool and solidify, which forms a bond between the materials.

- Cooling and Inspection: Once the weld has melted, it’s given time to cool, and then its quality is checked to make sure it meets the required standards.

TYPES OF LASER WELDING

Below, I list different laser welding techniques. Continuous Wave and Pulsed laser welding are the most commonly used laser welding modes used with handheld laser welders like LightWELD. Keyhole and Hybrid laser welding are more advanced techniques that require complex optics and robotic setups.

1. CONTINUOUS WAVE (CW) LASER WELDING

Continuous wave (CW) laser welding uses a laser beam that delivers constant, uninterrupted energy to the material, creating a steady, smooth weld seam. This type of laser welding is particularly well-suited for applications requiring consistent penetration depths and high-speed welding of longer seams. CW laser welding mode is great for welding thicker materials and producing deep, narrow weld profiles with minimal distortion. This is the most common weld setting. Most handheld welders operate in this mode. Some highly reflective materials require pulsed welding mode, however. I will describe it below.

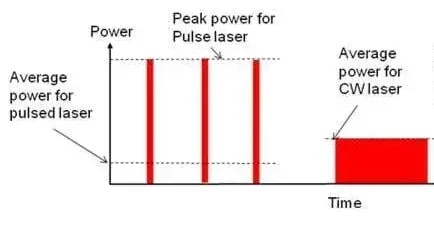

2. PULSED LASER WELDING

Pulsed laser welding uses short, controlled bursts of laser energy instead of a continuous beam. These quick, powerful pulses provide greater precision over heat input, making this mode especially beneficial when welding delicate components such as thin metal films or sheet metal. Pulsed welding is also ideal for highly reflective materials like aluminum and copper, where sharp bursts of peak energy are required to overcome reflectivity and achieve deeper penetration. For example, handheld laser welders like the LightWELD 2000XR leverage pulsed mode to reach peak powers of up to 2500 watts, despite having a continuous rating of 2000 watts. This enhanced peak power ensures effective welds even in challenging reflective materials. Additionally, because heat exposure is brief and highly controlled, pulsed welding significantly reduces thermal distortion and overheating risks. Pulsed laser welding is the preferred choice for precision-critical industries such as medical devices and aerospace manufacturing.

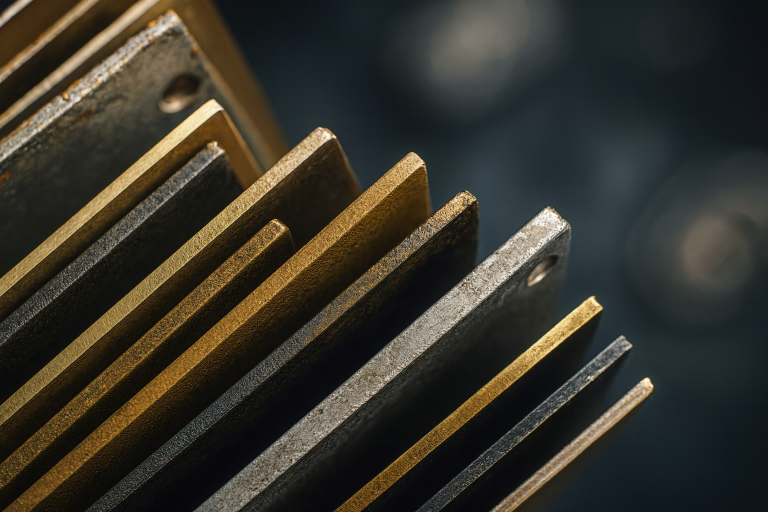

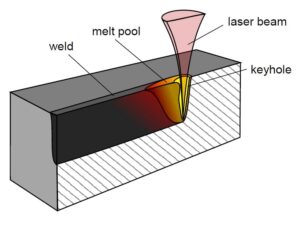

3. KEYHOLE LASER WELDING

Keyhole laser welding is a technique where the laser’s energy vaporizes the material at the welding point, creating a tiny “keyhole” in the metal. This allows for deeper welds, which is best for thicker materials or situations where deep penetration with minimal distortion is needed. It’s generally used in fields that require welding thick metals at high speeds or simply extremely precise autogenous (without filler wire) welds on car body parts. Keyhole welding is usually a high-power process that requires complex optics and a robotic arm or gantry carrying the heavy lenses.

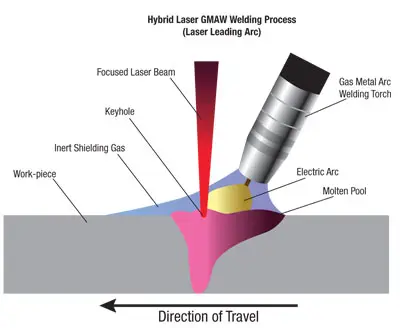

4. HYBRID LASER WELDING

Hybrid laser welding combines laser welding with another welding process, usually MIG. The hybrid technique combines the speed and consistency of the laser with the high deposition rates from the arc process. Hybrid laser welding is ideal for welding thicker materials or materials with complex geometries. This method is particularly favored in heavy industries, where high-speed, high-volume welds are required.

WHAT TYPES OF LASERS CAN WELD?

Handheld laser welders use fiber optics to oscillate and deliver the laser beam from the source to the gun. They fall under the fiber laser category. However, there are also other ways to create and deliver laser beams. Here is the comaprison between different laser types:

Laser Type | Characteristics | Common Applications |

CO2 Lasers | Known for their power and flexibility | Welding materials like steel, stainless steel, and aluminum |

Fiber Lasers | High efficiency and excellent beam quality | Welding materials such as copper, aluminum, and high-strength alloys |

YAG Lasers | Designed for deep penetration welding | Often used in aerospace and automotive sectors |

Diode Lasers | Small, energy-efficient, and precise | Detailed welds in disciplines like medical device manufacturing |

Get A Safety Enclosure

WHAT ARE THE ADVANTAGES OF LASER WELDING?

Laser welding is compatible with a broad range of materials, specifically metals and alloys. Some of the most commonly welded materials include:

- Steel (including carbon steel, stainless steel, and tool steel)

- Aluminum and its alloys

- Titanium and titanium alloys

- Copper and copper alloys

- Nickel and nickel alloys

- Gold and other precious metals

- Plastics (in some cases, especially in the automotive and medical industries)

One of the most critical advantages of laser welding is that it completely eliminates arc blow, a common obstacle in traditional arc welding caused by magnetic fields. These fields can deflect the welding arc, make it unstable, and force it to wander away from the intended weld path. By removing this issue, laser welding ensures precise, high-quality welds. This, combined with its ability to work with a variety of materials, makes laser welding invaluable in industries like high-end electronics and aerospace.

EXAMPLES OF LASER WELDING MACHINES

Laser welding machines are available in various configurations to meet the specific needs of different domains. Some examples include:

1. BATTERY WELDING MACHINES (REMOTE WELDING)

Battery welding machines are built to weld the delicate parts of batteries, like those found in electric vehicles (EVs) and mobile devices. They use precise lasers to join terminals, electrodes, and battery packs while making sure not to damage any sensitive components. These are very expensive and require complex optics.

2. HANDHELD LASER WELDING SYSTEMS

Handheld laser welding machines are amazing for sheet metal and other high-precision jobs. (Though they are very well capable of welding 0.25″ steel in a single pass) They supersede other traditional welding methods on all fronts. Laser welders are 4x faster than TIG, put in significantly less heat into the parts, and allow the operator to tune the weld bead width down to 0.1mm. They also produce repeatable results every single time because there is no arc blow, and the wobble width is just one of many parameters that can be precisely tuned.

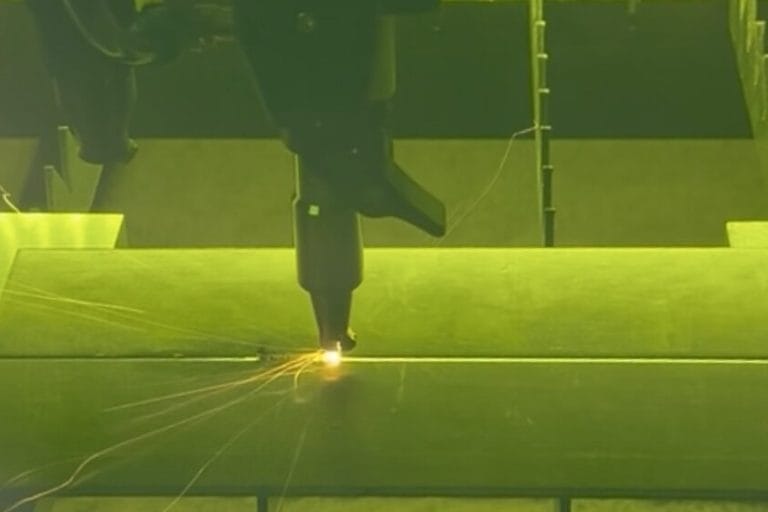

3. ROBOT WELDING MACHINES (REMOTE WELDING)

Robot welding systems use robotic arms paired with remote laser welding optics to automate the entire welding process. These systems are the right option for high-volume production and are widely used in the automotive industry to weld car frames and other structural components autogenously (without filler metal).

4. LASER WELDING COBOTS

Cobots are robots that are safe to be placed in close proximity to humans. They have safety logic that stops the cobot’s motion if it collides with a human. They also have limitations on joint motor power so that even if the safety logic fails, they are unlikely to severely hurt the operator. Cobots are great for automating parts with simple geometries and relatively high production runs. Together with a LightWELD handheld laser welder, a cobot laser welder cell is indispensable for most sheet metal manufacturers.

WHAT ARE THE APPLICATIONS OF LASER WELDING?

Some of the most prominent sectors that rely on laser welding technology include:

1. AUTOMOTIVE INDUSTRY

In the automotive industry, laser welding is popularly used to manufacture car bodies, exhaust systems, engine parts, and battery assemblies. Its precision and speed make it best for creating the complex components and joints found in modern vehicles. Laser welding is also often used in the assembly of electric vehicles (EVs), where its ability to create lightweight, detailed welds is vital.

2. AEROSPACE INDUSTRY

The aerospace industry demands high-strength, lightweight materials, and laser welding is the most suitable and efficient method for joining components made of aluminum, titanium, and other alloys. Laser welding is used for assembling airframes, engine parts, fuel systems, and other critical components where structural integrity and consistency are essential.

3. MEDICAL DEVICES

Laser welding is widely used in the medical device market to create precision parts such as surgical instruments, implants, and medical equipment. The ability to weld small, delicate components without causing thermal damage is especially valuable in this sector. Additionally, the clean, sterile welds produced by laser welding are essential for medical applications.

4. ELECTRONICS MANUFACTURING

Laser welding is frequently used in electronics manufacturing to join delicate parts like connectors, circuit boards, and other small components. Thanks to its precision, laser welding can fuse these tiny parts without damaging sensitive electronics or causing overheating.

5. ENERGY SECTOR

Laser welding is employed in the energy sector for the construction and maintenance of power plants, oil rigs, and renewable energy systems. It’s most useful for welding thick materials and creating strong, dependable joints that can handle high pressure and extreme temperatures.

6. JEWELRY MANUFACTURING

Laser welding is becoming more popular in the jewelry business for creating detailed designs, repairing pieces, and joining precious metals. Its neatness and low heat output make it perfect for working with delicate, valuable materials.

Conclusion

Laser welding is one of the most advanced and versatile joining technologies available today. By using a concentrated beam of light, it delivers extremely precise, high-quality welds with minimal heat distortion.

Whether you’re working with delicate medical components, automotive assemblies, or thick structural parts, laser welding offers the speed, repeatability, and adaptability that traditional welding methods often cannot match.

Laser welding is the technology of the future. As industries continue to push for lighter, stronger, and more complex designs, laser welding is gaining more and more popularity among companies who care about quality. Other methods do have their niche applications, but laser welding truly beats them in most applications.

FAQs

1. Can laser welding replace traditional MIG or TIG welding?

In most cases, yes. Laser welding is significantly faster, cleaner, and more precise than MIG or TIG. It produces minimal spatter, requires less post-weld cleanup, and creates strong, consistent welds, but while keeping minimal distortion on thin or delicate materials. While MIG and TIG still have their place for certain heavy-fill or out-of-position applications, laser welding is quickly becoming the preferred choice for shops that work with tight specs and value high quality.

2. What materials can be laser welded?

Laser welding can join a wide range of materials, including carbon steel, stainless steel, aluminum, titanium, copper, and even some plastics. Its versatility makes it ideal for industries from aerospace to medical device manufacturing.

3. Is laser welding safe to use in a regular shop environment?

Yes. Laser welding systems are designed with features like interlocks and plume detectors, but operators must still use laser-safe enclosures or designated welding areas. With the right setup, laser welding can be just as safe as traditional arc welding methods.

4. What are the biggest advantages of laser welding over other welding processes?

The key advantages are precision, speed, and minimal heat distortion. Laser welding creates a very small heat-affected zone (HAZ), which means parts stay dimensionally accurate. It also eliminates problems like arc blow, allowing for cleaner, repeatable welds with less post-processing.

About The Author

Emma Ascott is a journalist specializing in technological subjects, with a bachelor’s in Journalism and Mass Communication from Arizona State University. She has worked for Arizona PBS, nuclear fusion company TAE Technologies, and Future of Work publication Allwork.Space. Emma is the PR lead at MavWeld.